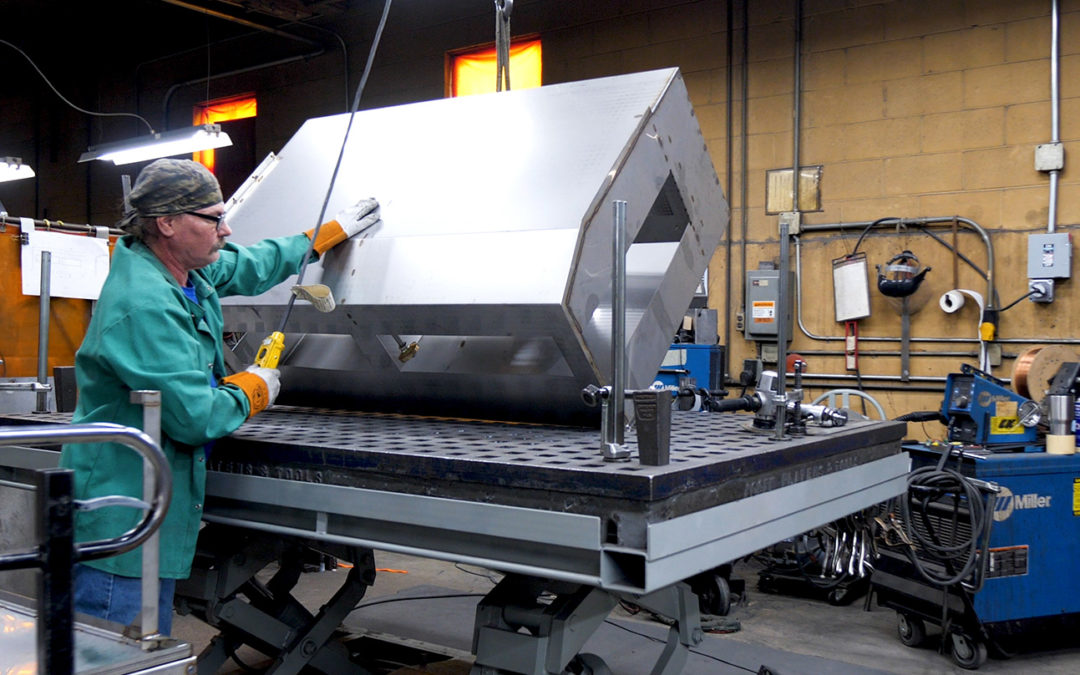

When it comes to manufacturing, precision is key. Every piece of machinery and equipment must be crafted with accuracy and precision to ensure that it functions properly and effectively. This is where precision sheet metal comes into play. Precision sheet metal fabrication refers to the process of creating precise metal parts and components through a variety of cutting, bending, and punching techniques. In this article, we will explore the importance of precision sheet metal in manufacturing and how it is revolutionizing the industry.

Precision sheet metal offers superior quality

Precision sheet metal fabrication enables manufacturers to produce parts and components with a high degree of accuracy and consistency. This means that every piece of equipment or machinery will be of superior quality, and customers will be able to rely on it for optimal performance. With precision sheet metal, manufacturers can produce parts with tight tolerances, ensuring that they fit together perfectly and operate smoothly.

Precision sheet metal is cost-effective

With precision sheet metal, manufacturers don't need to invest in expensive tooling or equipment to produce high-quality parts. Instead, they can rely on state-of-the-art machinery and advanced software to craft components with exceptional accuracy. This also means that manufacturers can produce parts in large quantities without sacrificing quality or consistency. Additionally, precision sheet metal parts are lightweight and durable, making them a cost-effective choice for a variety of applications.

Precision sheet metal allows for complex designs

Precision sheet metal fabrication techniques allow manufacturers to produce parts and components that are both intricate and complex. With computer-controlled cutting and bending tools, manufacturers can fashion intricate designs that would be impossible with traditional metalworking techniques. This means that manufacturers can create parts and components that are both aesthetically pleasing and highly functional, making them ideal for a wide range of applications.

Precision sheet metal is versatile

Precision sheet metal is used in a variety of industries, including automotive, aerospace, medical, and electronics. This versatility is due to the fact that sheet metal can be fabricated in a variety of thicknesses, from thin, flexible sheets to thicker, more robust ones. Additionally, precision sheet metal can be shaped, cut, and bent to create a wide range of parts and components, making it an indispensable material for modern manufacturing.

Precision sheet metal is sustainable

Precision sheet metal fabrication techniques use only the amount of material that is necessary to create a specific part or component. This means that there is very little waste or scrap left over after a project is complete. Additionally, precision sheet metal is highly recyclable, meaning that it can be reused over and over again, reducing the environmental impact of manufacturing.

Conclusion: Precision sheet metal is revolutionizing the manufacturing industry by allowing manufacturers to produce high-quality, cost-effective, complex, and versatile parts and components. Additionally, precision sheet metal is sustainable, making it an ideal choice for companies that are environmentally conscious. As the demand for precision parts and components continues to grow, we can expect to see even more innovation in the field of precision sheet metal fabrication. Whether you're in the automotive, aerospace, medical, or electronics industry, precision sheet metal is a vital part of modern manufacturing.

icons at the top right corner of the subsection.

icons at the top right corner of the subsection.